SECTORS IN WHICH WE OPERATE

Cleaning the component in the aeronautical sector is a very delicate and critical operation, as the components are often made of sensitive and complex materials that require very accurate treatment.

The cleaning of aeronautical components must be most accurate, eliminating any contamination and lubricant residues, while at the same time it must not compromise the quality and integrity of the components themselves.

Cleaning the components in the mechanical sector is a very important operation to ensure maximum efficiency and durability of the components themselves.

Mechanical components, in fact, are often exposed to contamination such as grease, oil, dust and other processing residues that can compromise their functionality and durability over time.

Cleaning the components in the medical sector is a very critical and important operation to ensure maximum safety and hygiene in medical processes. Medical components, in fact, are exposed to organic and bacterial contamination, and require a very accurate treatment to remove any trace of contaminant.

The cleaning of components in the eyewear sector is a very important operation to ensure maximum hygiene and cleanliness of the glasses and their components. Glasses are exposed to different types of contaminants, such as makeup, grease and dust, which can compromise their transparency and the effectiveness of the lenses.

The cleaning of components in the jewellery sector is a very important operation to ensure the maximum cleanliness and hygiene of the jewellery. Jewellery items, such as rings, necklaces, earrings, bracelets, and other components, can accumulate particles of dirt, grease, and dust, which can impair their appearance and lustre.

The automotive industry requires cleaning numerous components such as engine parts, body parts, electronic parts, brakes and many other parts that can accumulate dust, grease, oils, rust and other substances during their operating life.

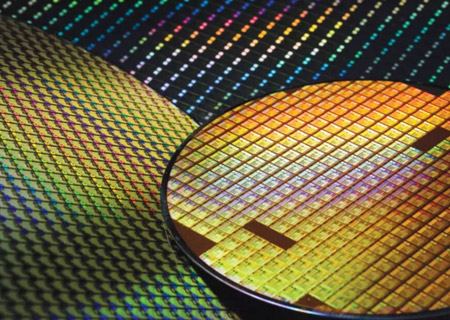

The galvanic sector involves the processing of numerous metal components and semiconductors through the application of metal coatings. During this process, components can accumulate dirt, oils and process residues that must be removed before applying the coating.

Tools and components used during the dental implant process. Ultrasonic cleaning is an ideal solution to ensure an accurate and efficient cleaning of these instruments.

The silicon wafer production process requires thorough cleaning of the components used, such as silicon crystals and machining equipment. These components must be thoroughly cleaned to ensure that the production of the wafers takes place smoothly and that the wafers themselves are not damaged by particles or contaminants.