Wet benches

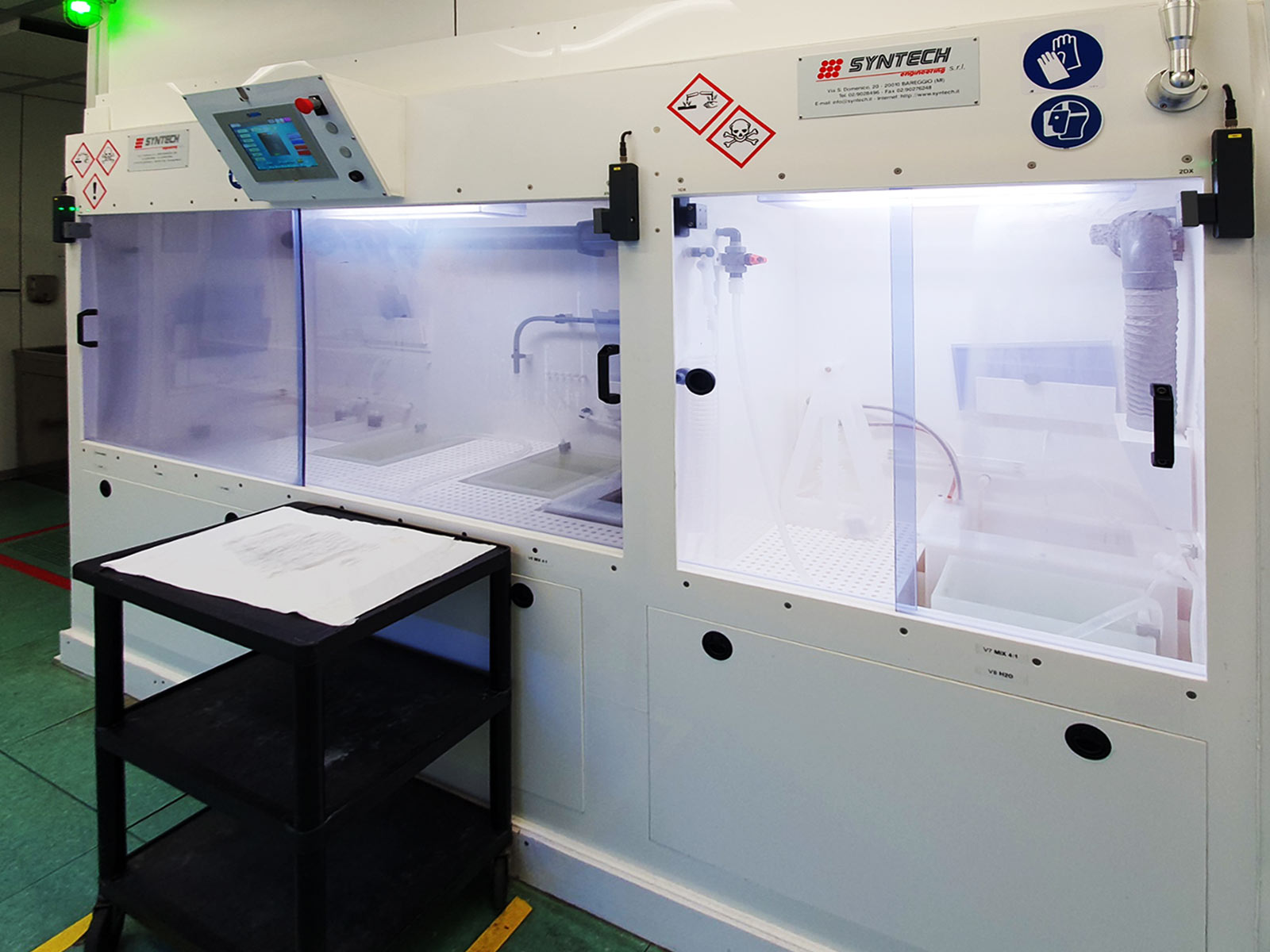

Our wet wenches are built with fine materials chosen by our designers in order to develop cleaning processes with different acid and basic substances, thus avoiding corrosion problems. The main structure as well as the interiors of the tanks are made of coated stainless steel or polymer (PP, PVC, PVDF).

All the cycle parameters can be controlled directly on the machine thanks to the HMI panel.

The products are located inside a basket which is moved from one tank to another either by the operator or by a cartesian robot specifically designed.

Special sensors ensure the safety of the operator, of the product and of the cleaning process.

Thanks to the high automation level of our wet benches, we supply remote assistance directly from our headquarters: this ensures that all our benches have the necessary features to be defined cutting-edge machines in compliance with the 4.0 industry.

Automated Wet Bench built with polymeric materials that can withstand numerous acidic substances. The WB7 consists of 7 cleaning tanks and stations dedicated to loading and unloading the baskets containing the products to be cleaned.

Through an HMI panel it is possible to set the automated cleaning processes and the parameters. The movement of the products between the different tanks is carried out by means of a custom-designed robot.

Automated Wet Bench made with polymeric materials that can withstand numerous acidic substances. The WB4 consists of 4 cleaning tanks and a station dedicated to loading and unloading the baskets containing the products to be cleaned. The cleaning processes are completely automatic and the parameters can be set through an HMI panel. The movement of the products between the different tanks is carried out by means of a custom-designed robot.

Automated Wet Bench made of polymeric materials able to withstand numerous acidic substances. The WB6+2 is composed of 8 cleaning tanks and is divided into two parts to improve the insulation of special treatments. The cleaning processes are completely automatic and the parameters can be set through an HMI panel.

Automated Wet Bench made of polymeric materials able to withstand numerous acidic substances.

The WB3-5 is composed of 3 cleaning tanks, two of which are equipped with an agitation system that ensures a better cleaning of the products and allows an easy withdrawal of the basket. The cleaning processes are completely automatic and the parameters can be set through an HMI panel.

Automated Wet Bench made of polymeric materials able to withstand numerous acidic substances.

The WB3-50 consists of 3 washing tanks, two of which are heated and equipped with an ultrasonic cleaning system. The cleaning processes are completely automatic and the parameters can be set through an HMI panel.

Automated wet bench made of polymeric materials with an ultrasonic cleaning tank, a QDR tank and a large work surface that allows the operator to work in a clean environment with an exhaust suction system. The cleaning processes are completely automatic and the parameters can be set through an HMI panel.

Automated Wet Bench made of polymeric materials able to withstand numerous acidic substances. It consists of 8 cleaning tanks and a station dedicated to the loading and unloading of baskets, which contain the products to be cleaned, whose external movement takes place thanks to a conveyor belt. The cleaning processes are completely automatic and the parameters can be set through an HMI panel. The movement of the products between the different tanks is carried out by means of a custom-designed robot.